It’s important that the operator knows exactly which task they need to perform to complete the job.” “Our spindle line assembly consists of over 16 stations. Current workflows made it difficult to track WiP through the line. Without visibility into the work performed at each station, the company lacked the ability to identify bottlenecks and properly balance lines.

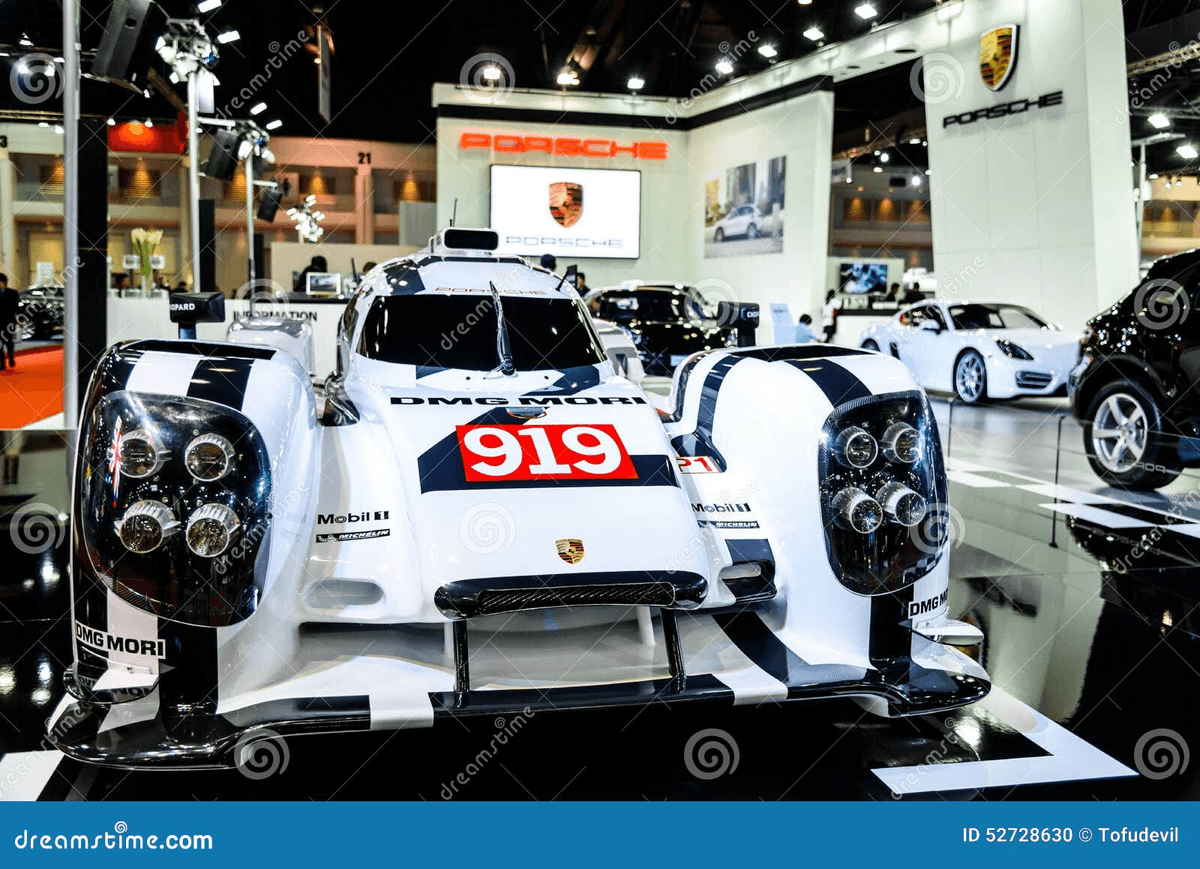

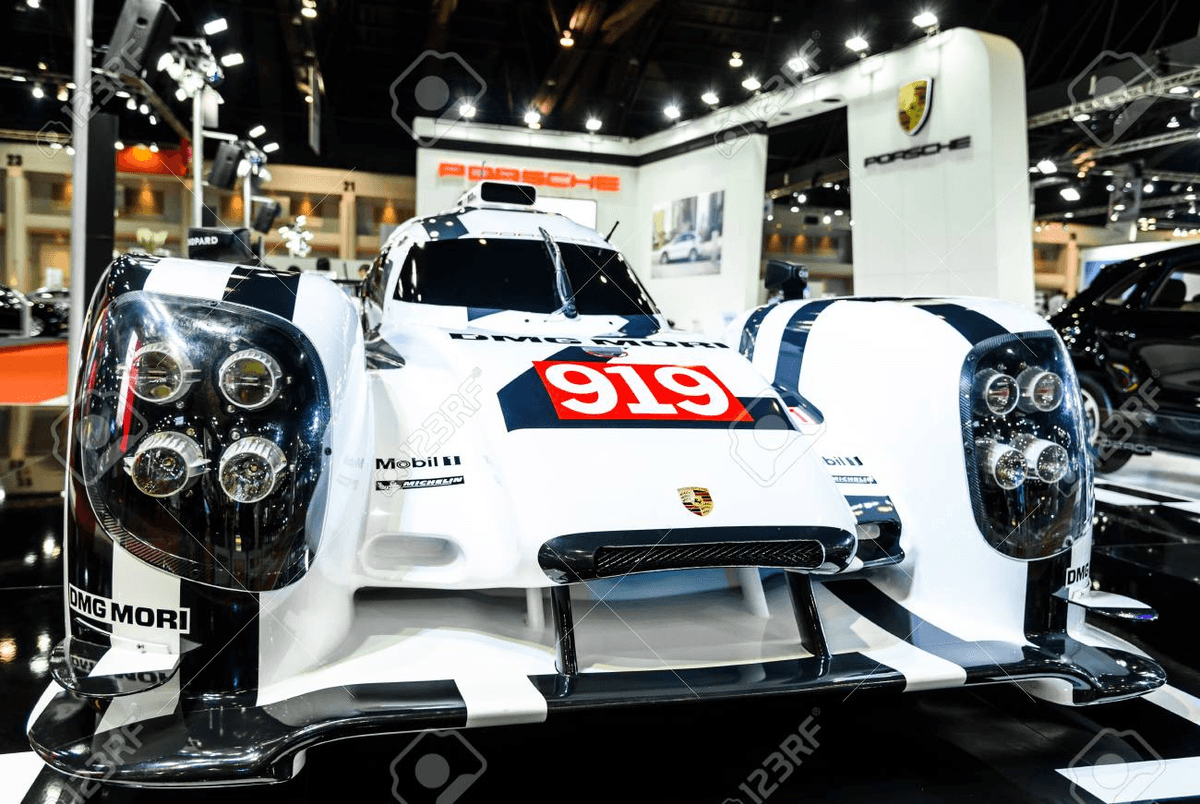

Without real-time data, finding patterns in production data was slow and prone to error.įinally, DMG MORI’s lines adhere to strict Takt times. When defects arose, they were recorded on additional paper forms. Work was recorded on paper forms, making it difficult to track progress in real time. While operators have access to paper schematics and standard work requirements, existing quality measures were time consuming and prone to error. Spindles move through a single-piece flow process spanning over a dozen stations.Įvery station includes highly variable picking procedures and quality checks. Each spindle is the product of a complex assembly. Serving customers in over 42 industries and 79 countries, DMG MORI strives to be “Global One Company”-leveraging the best of their German and Japanese heritage in our modern interconnected world.ĭMG MORI produces the spindles for many of their machines in-house. DMG MORI is a leading international manufacturer of machines and machine tools.